Moving Materials Is What We Do!

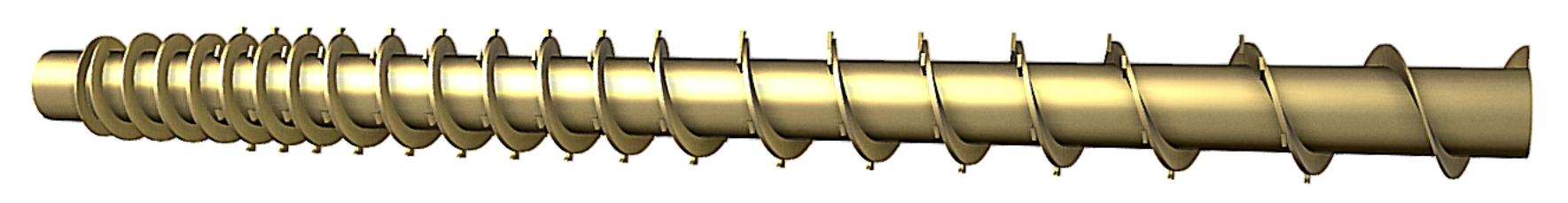

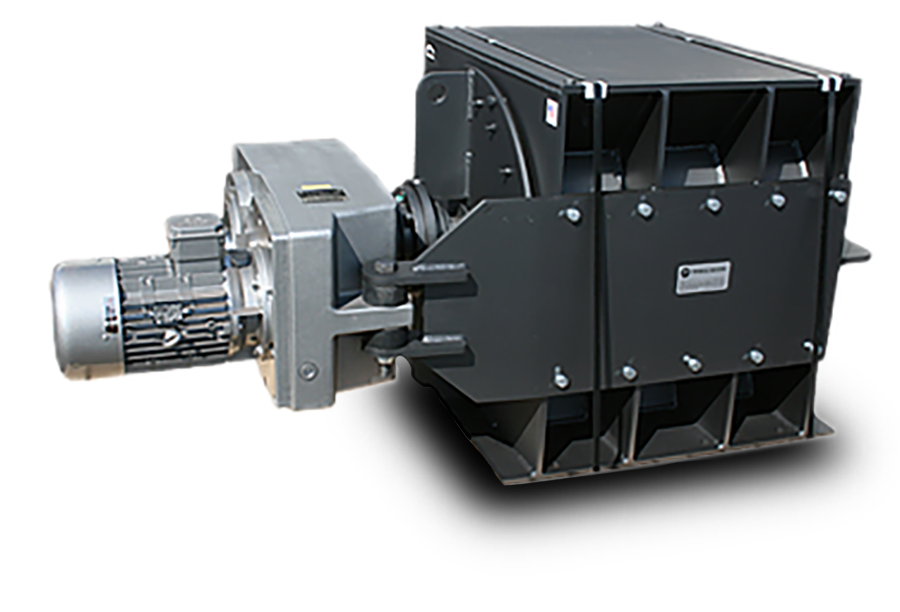

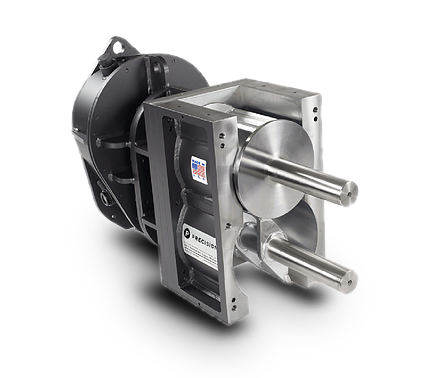

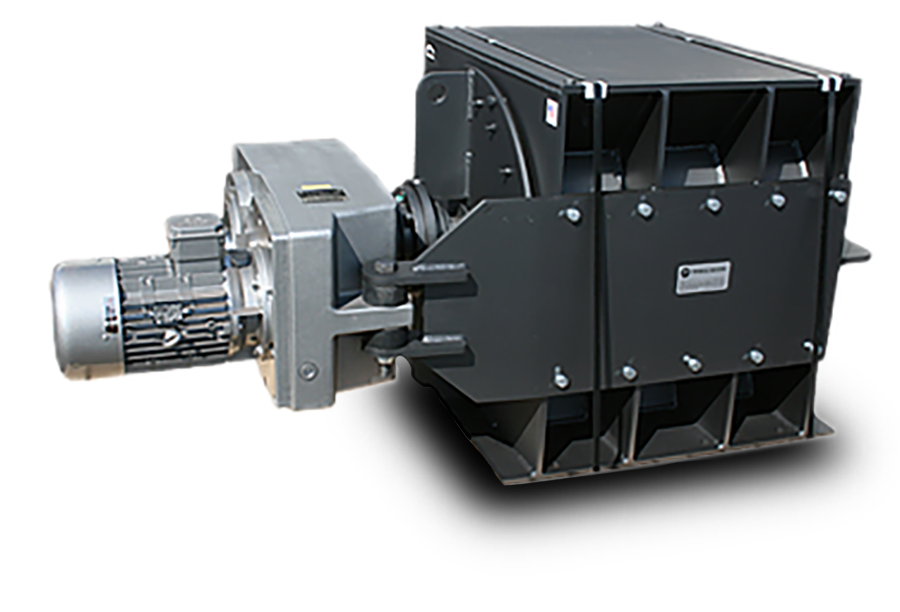

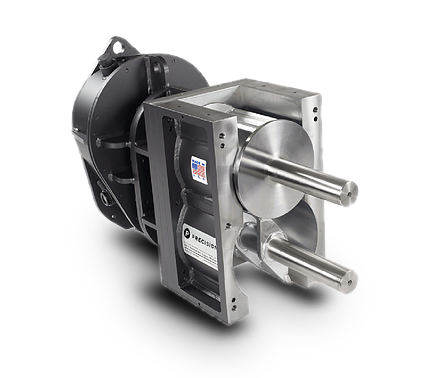

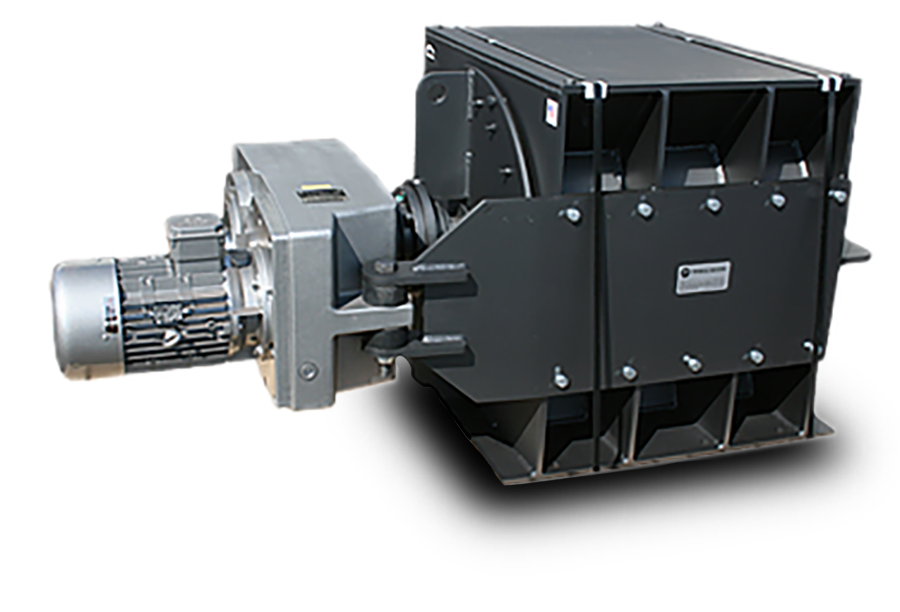

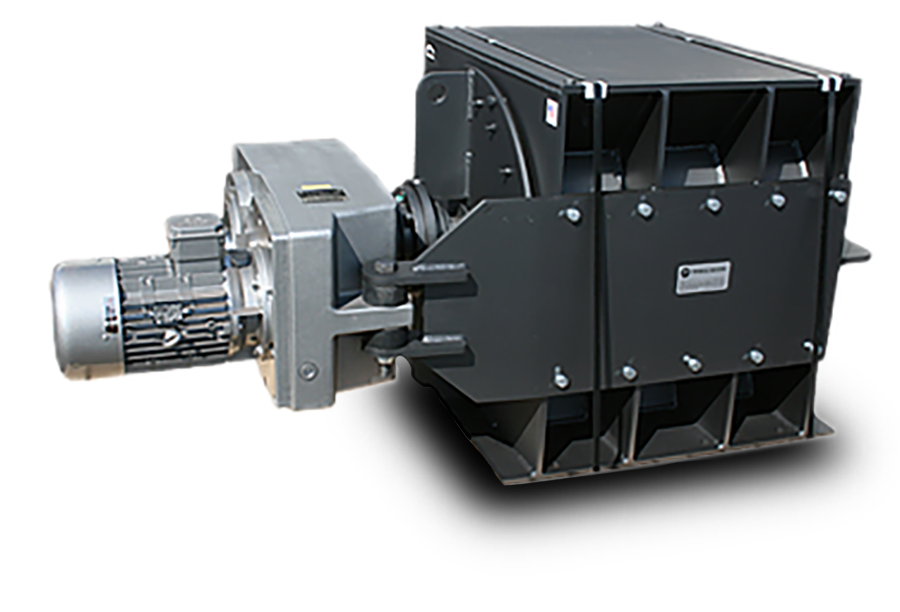

PMM’s Rotary Feeders/Airlocks, Rotary Valves, and Screw Conveyors simply move material more efficiently, with greater flow, and with far less downtime & maintenance costs.

Over-Engineered & Over-Built!

Why Precision?

Engineered Solutions

It all starts with the Application! Once we have gathered all of the relevant application data, we go to work engineering & designing a solution that will exceed the throughput requirements for the overall material handling system.

Industry leaders

Time and time again, we are called upon to solve material handling challenges that are the result of using inferior equipment. Through this process, we have emerged as the “go to source” for all material handling components.

Made in USA

All Rotary Feeders, Rotary Valves, Airlocks and Screw Conveyors are manufactured in the United States of America by hard-working Americans, and with materials sourced from this great land!

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

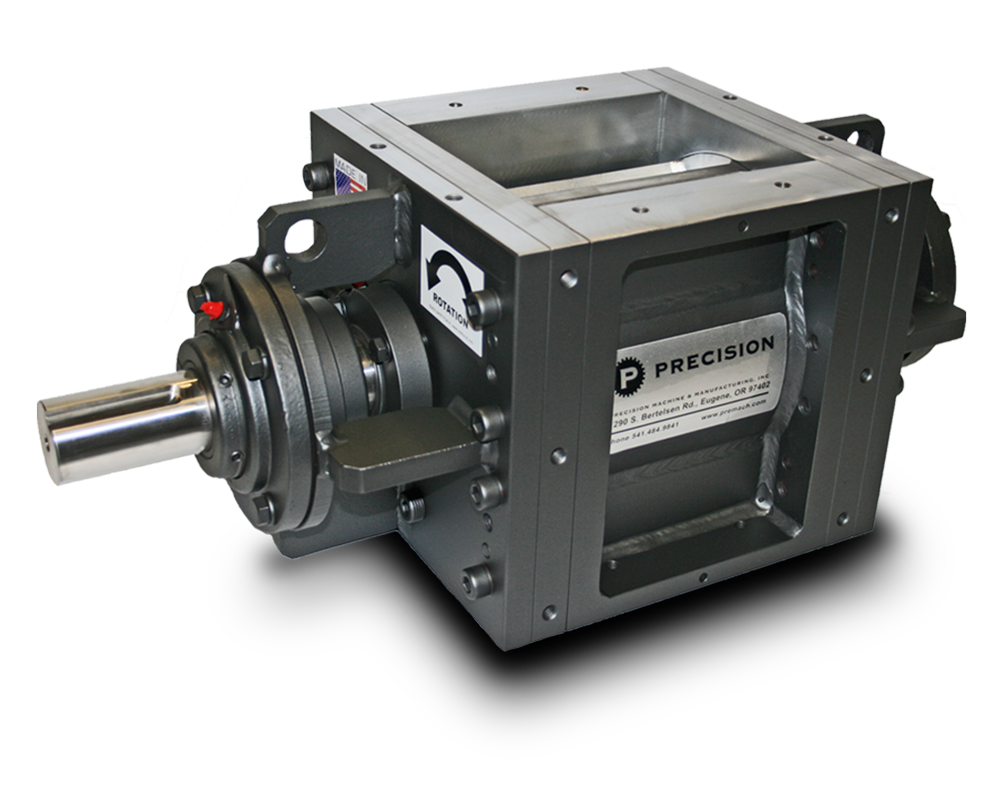

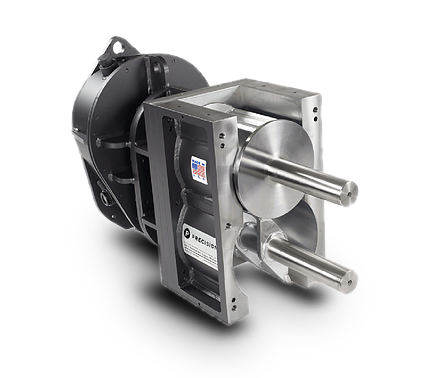

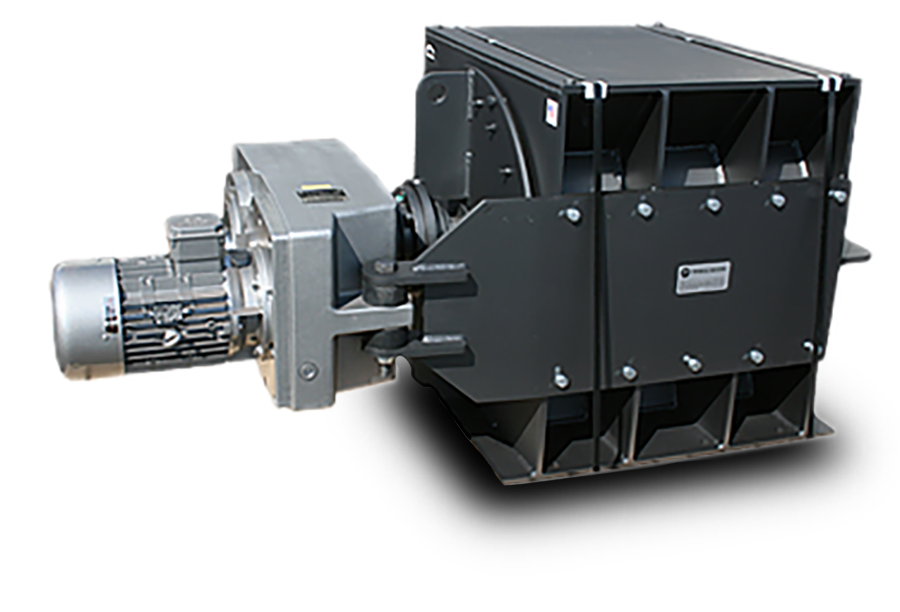

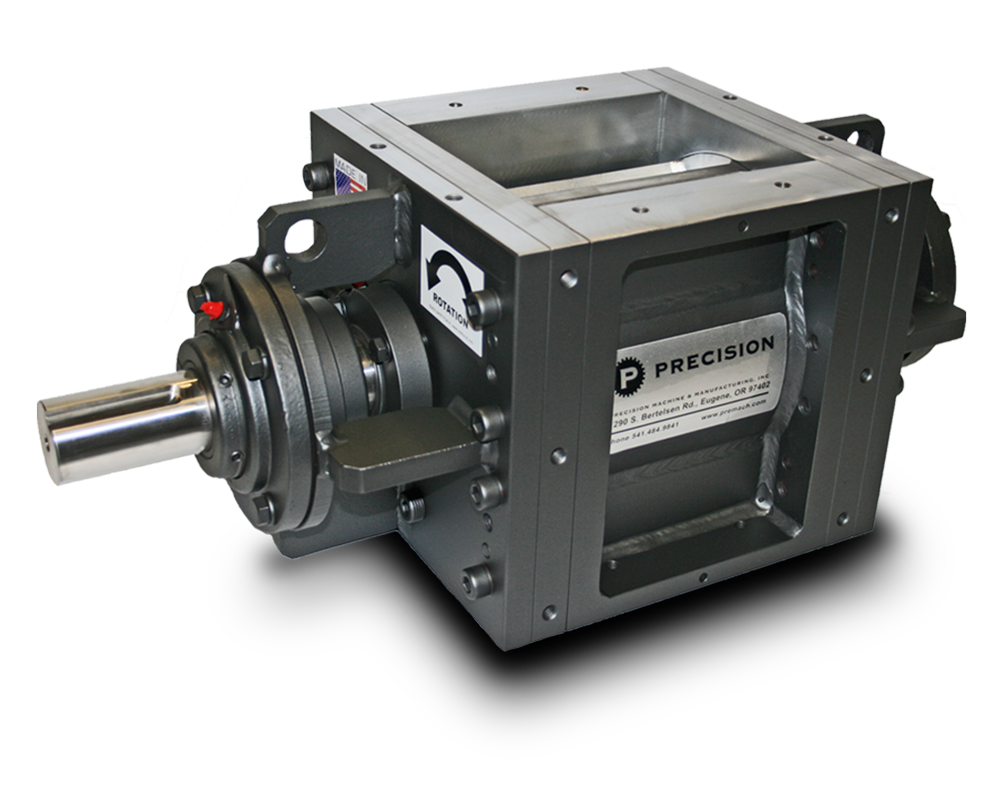

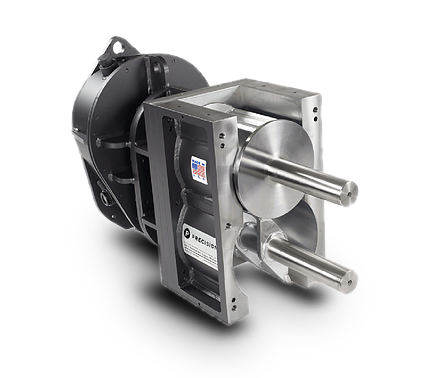

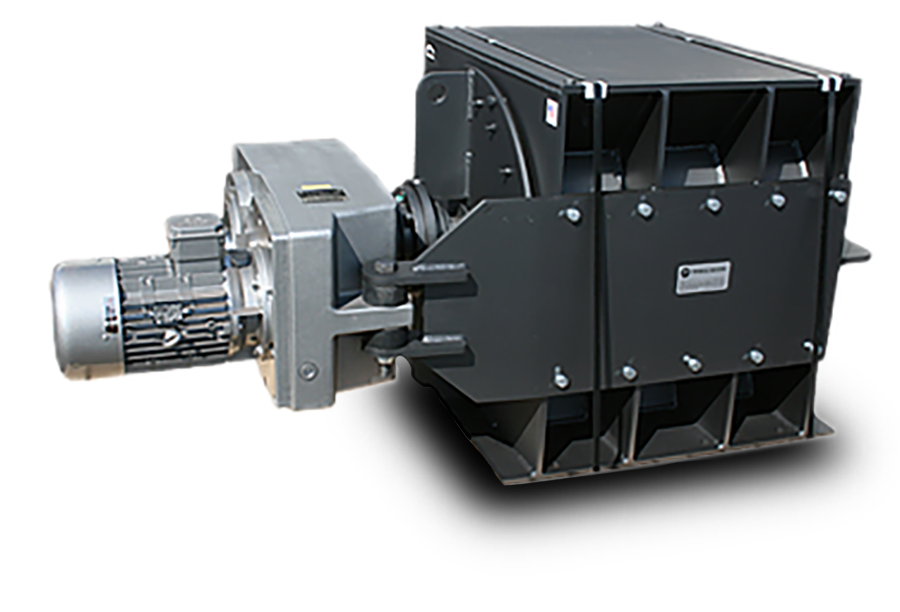

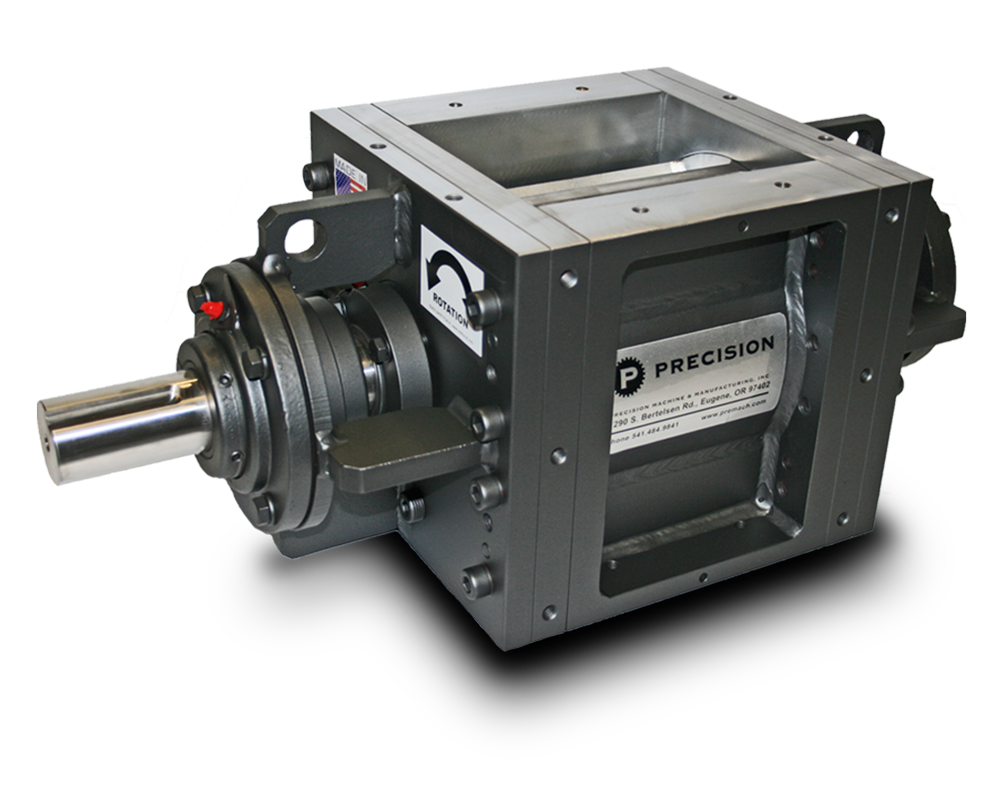

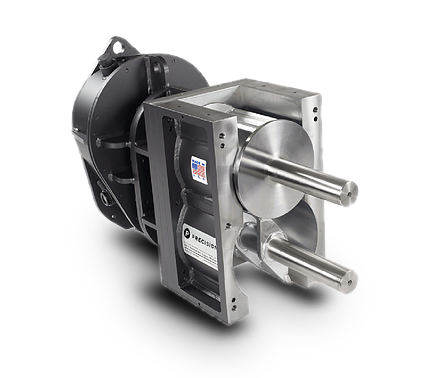

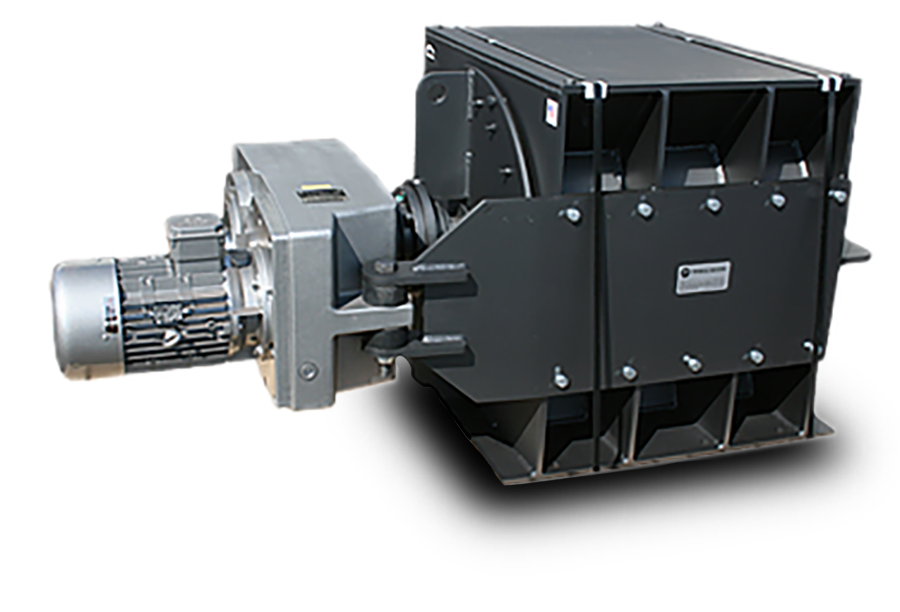

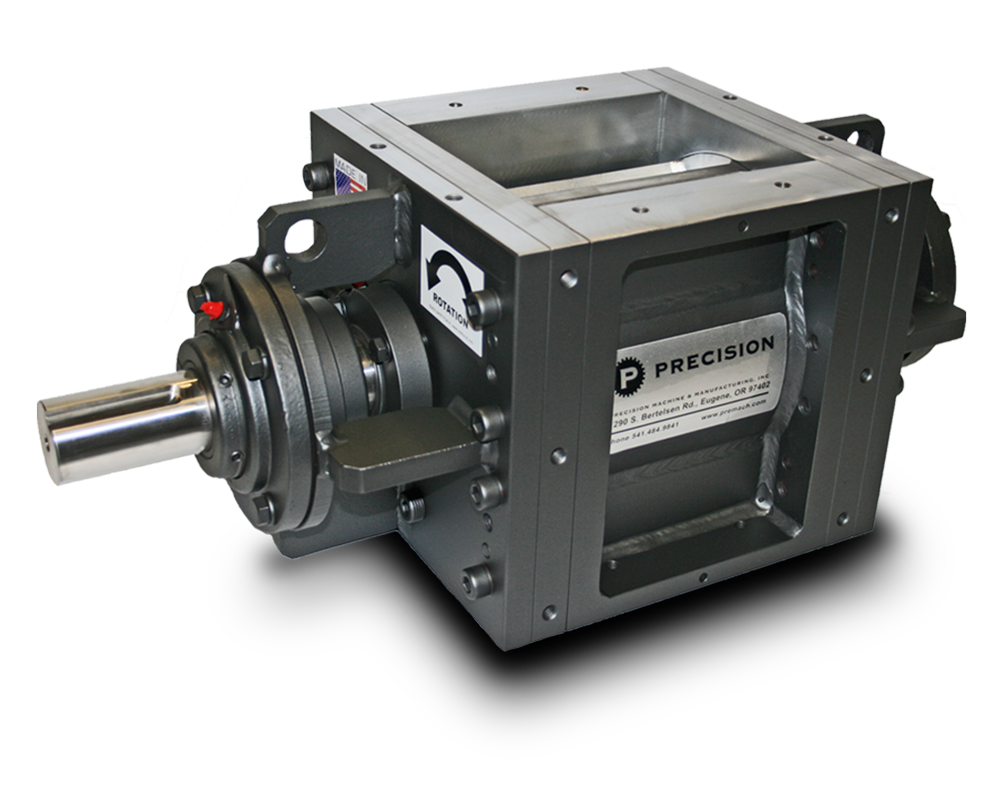

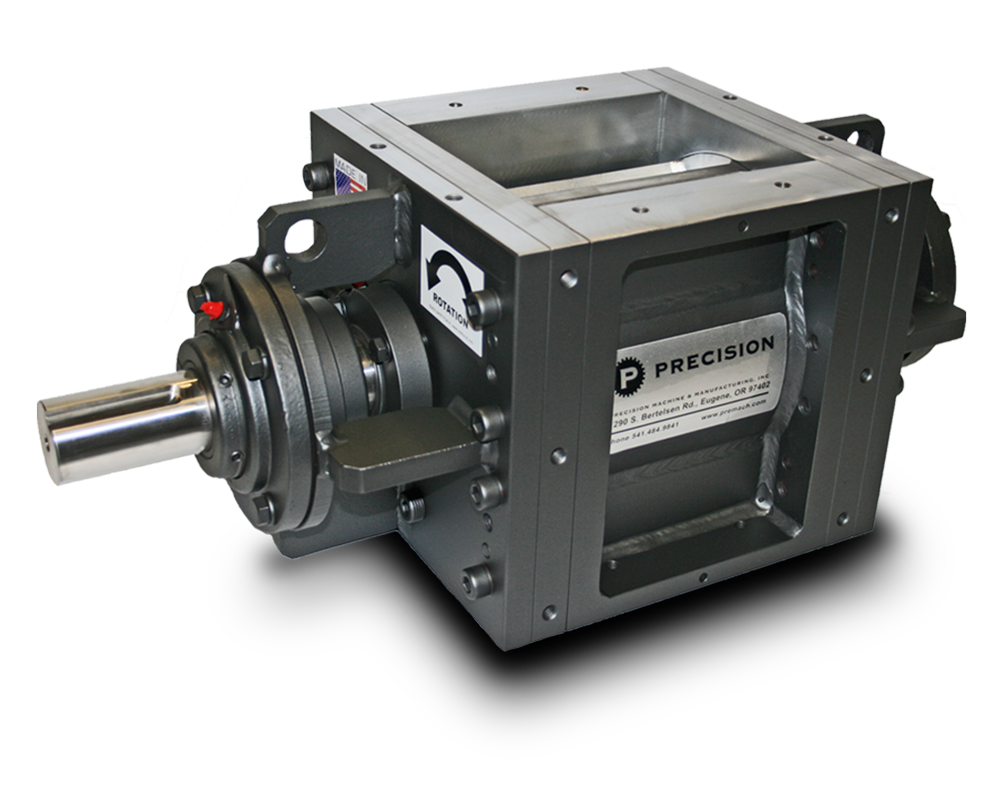

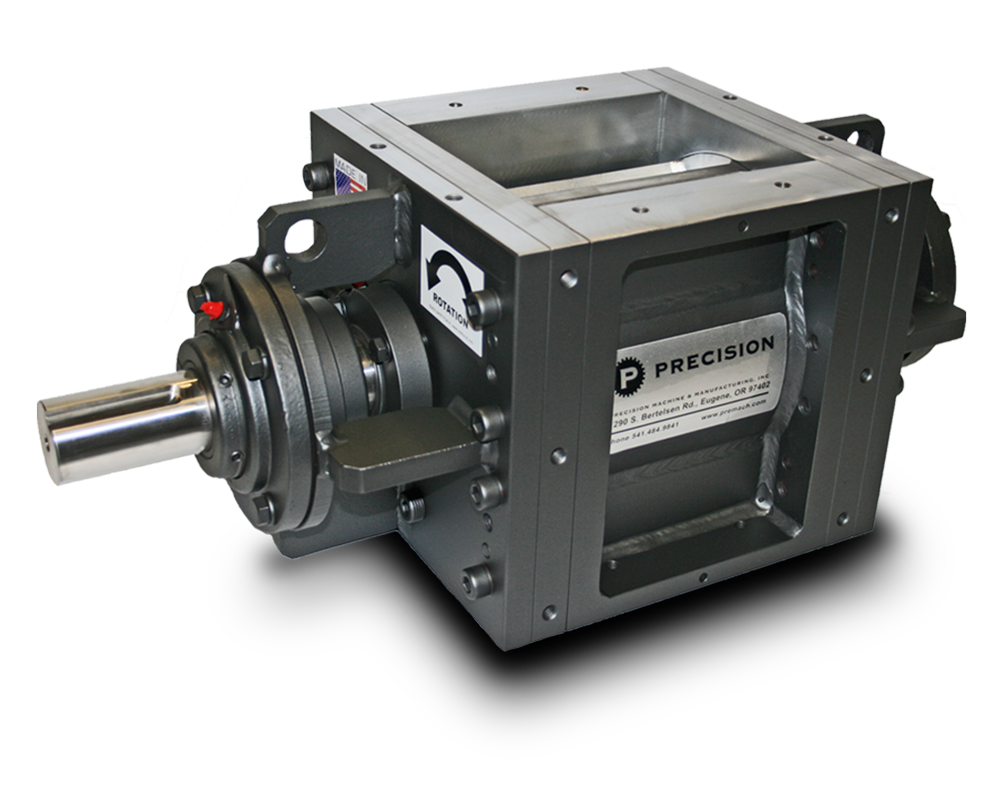

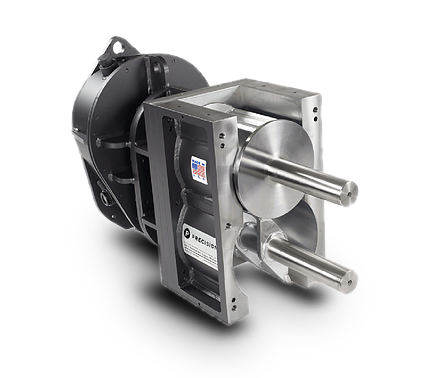

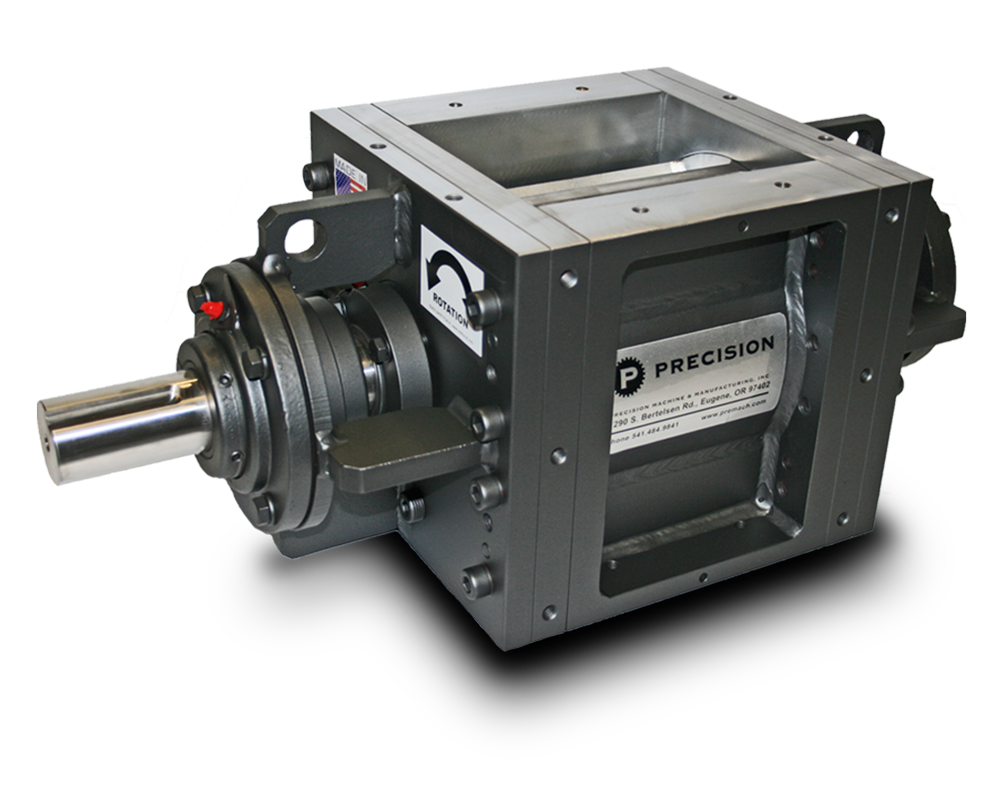

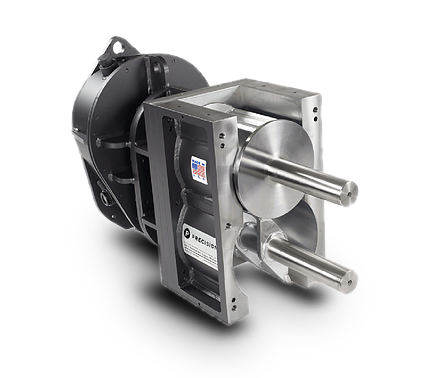

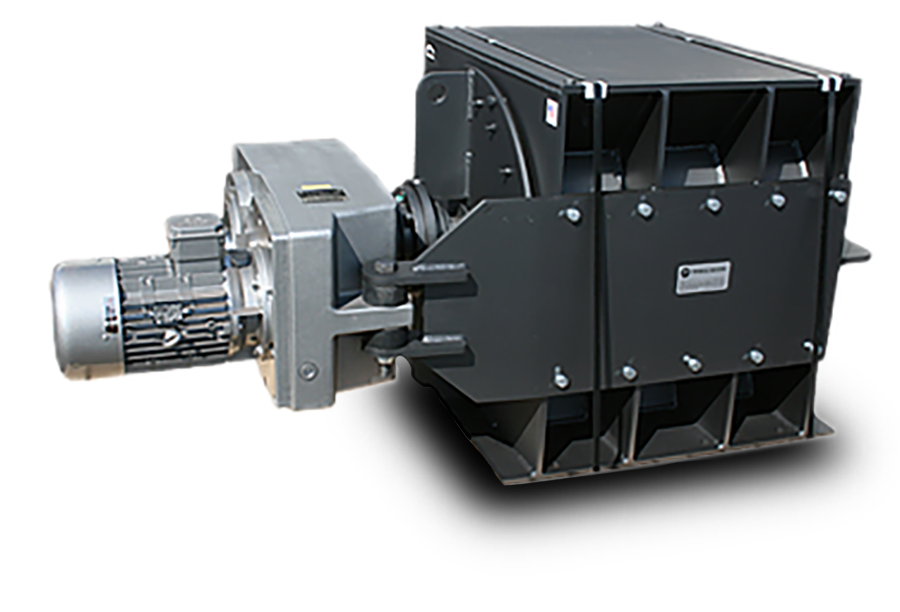

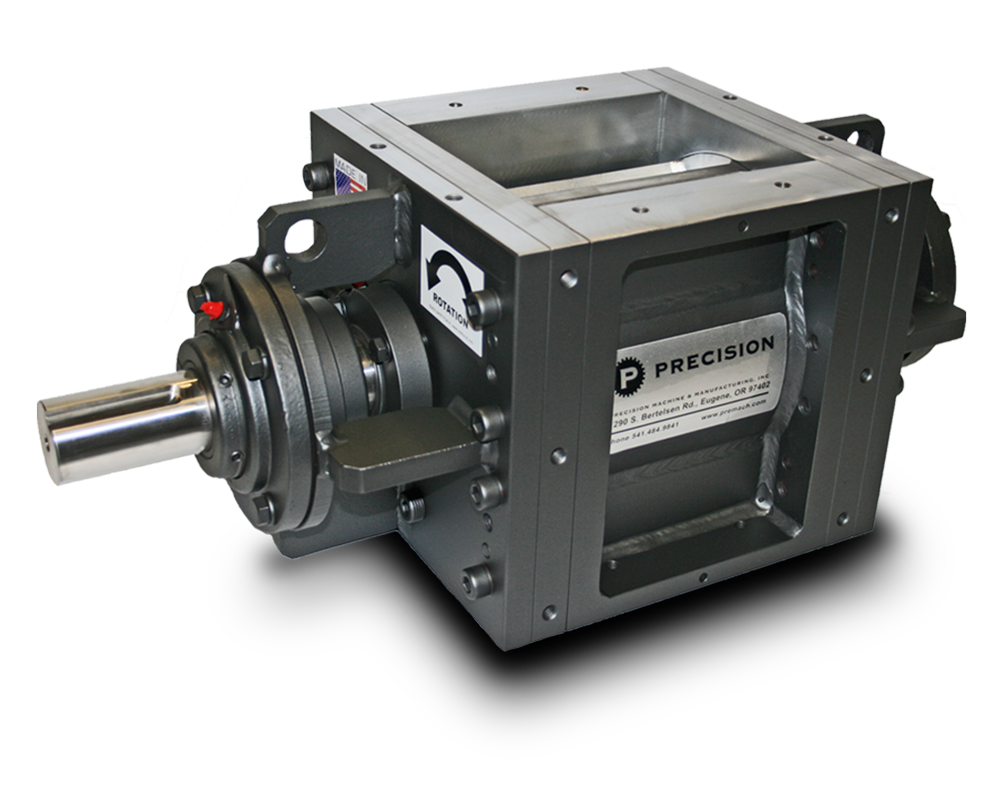

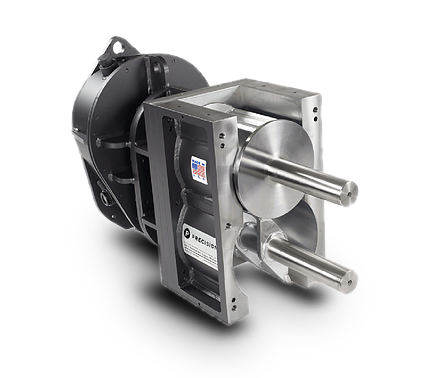

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

OVER ENGINEERED &OVER BUILT!

Why Precisions?