Automated Applications

We Design and Build Custom Solutions for

Automation for the Interconnect / Electronic Industries

and Other High Volume Applications

5212 Kazuko Court

Moorpark, CA 93021 U.S.A.

805-529-2424 ext 101

Automated Applications

We Design and Build Custom Solutions for

Automation for the Interconnect / Electronic Industries

and Other High Volume Applications

5212 Kazuko Court

Moorpark, CA 93021 U.S.A.

805-529-2424 ext 101

Automation

Custom Automated Equipment for the Interconnect / Electronic Industries and Other High Volume Applications

Automated Applications, Inc. offers a wide range of capability such as concept development, design, (controls, data, mechanical, electrical) fabrication, installation and service. Established in 1988, AAI has built a strong reputation based on reliable solutions implemented on time. Our record makes AAI the logical choice for automation in Interconnect, Electronic and other high volume environments.

Design

We work with your requirements to design your custom automated machine to build your parts

Build

We take the custom concept and design and create it!

Maintain/Service

Once your machine is built and delivered, we help you keep it going.

Products

Products

Your Specifications, Our Design, Your Solution

AAI Designs, Builds, and Maintains custom, automated machines for your specialized needs including -

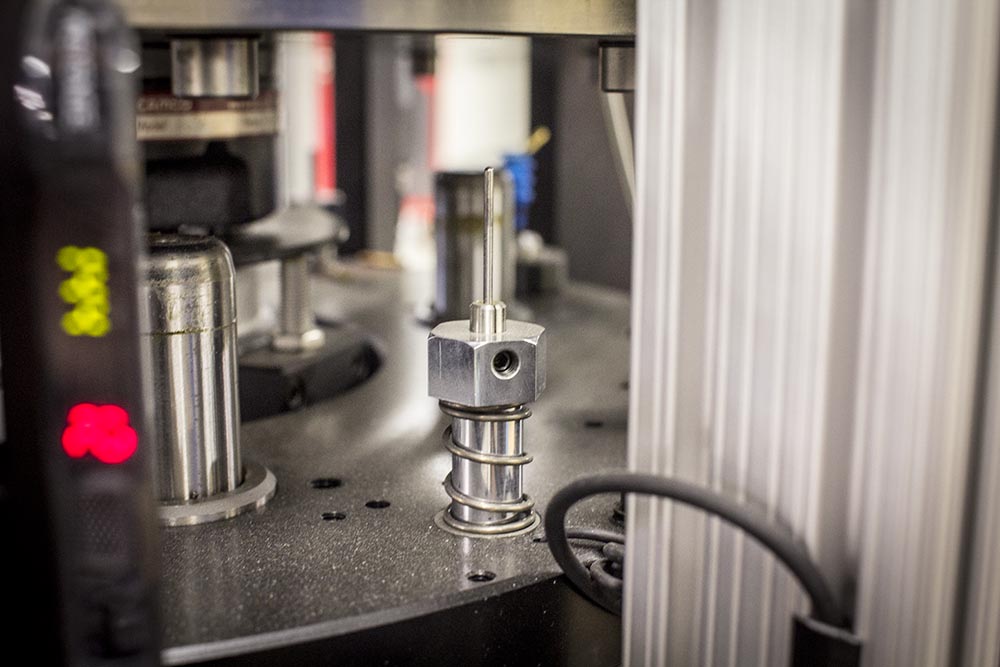

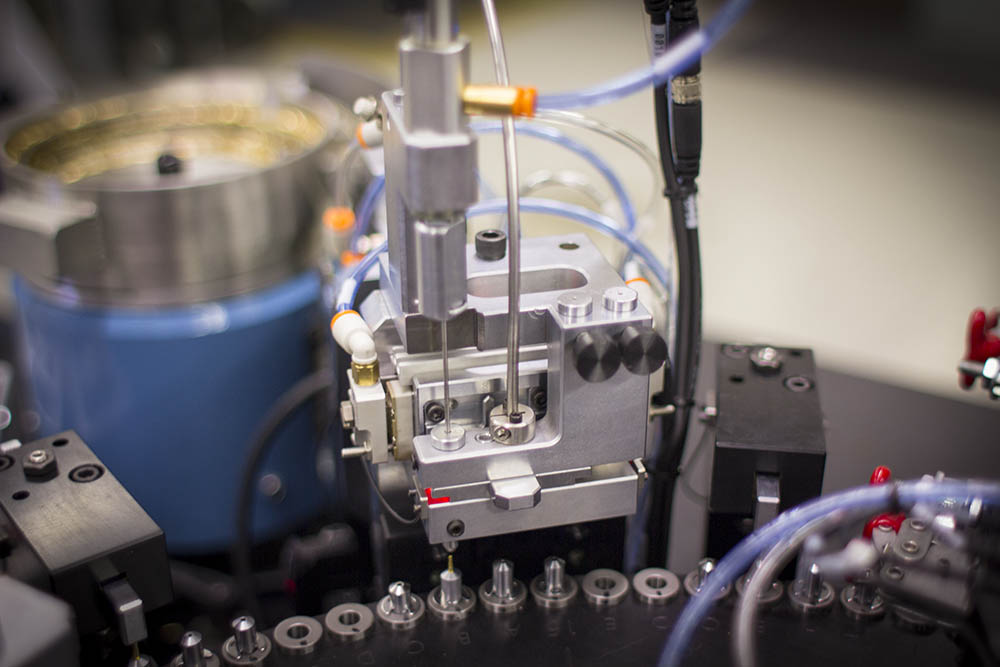

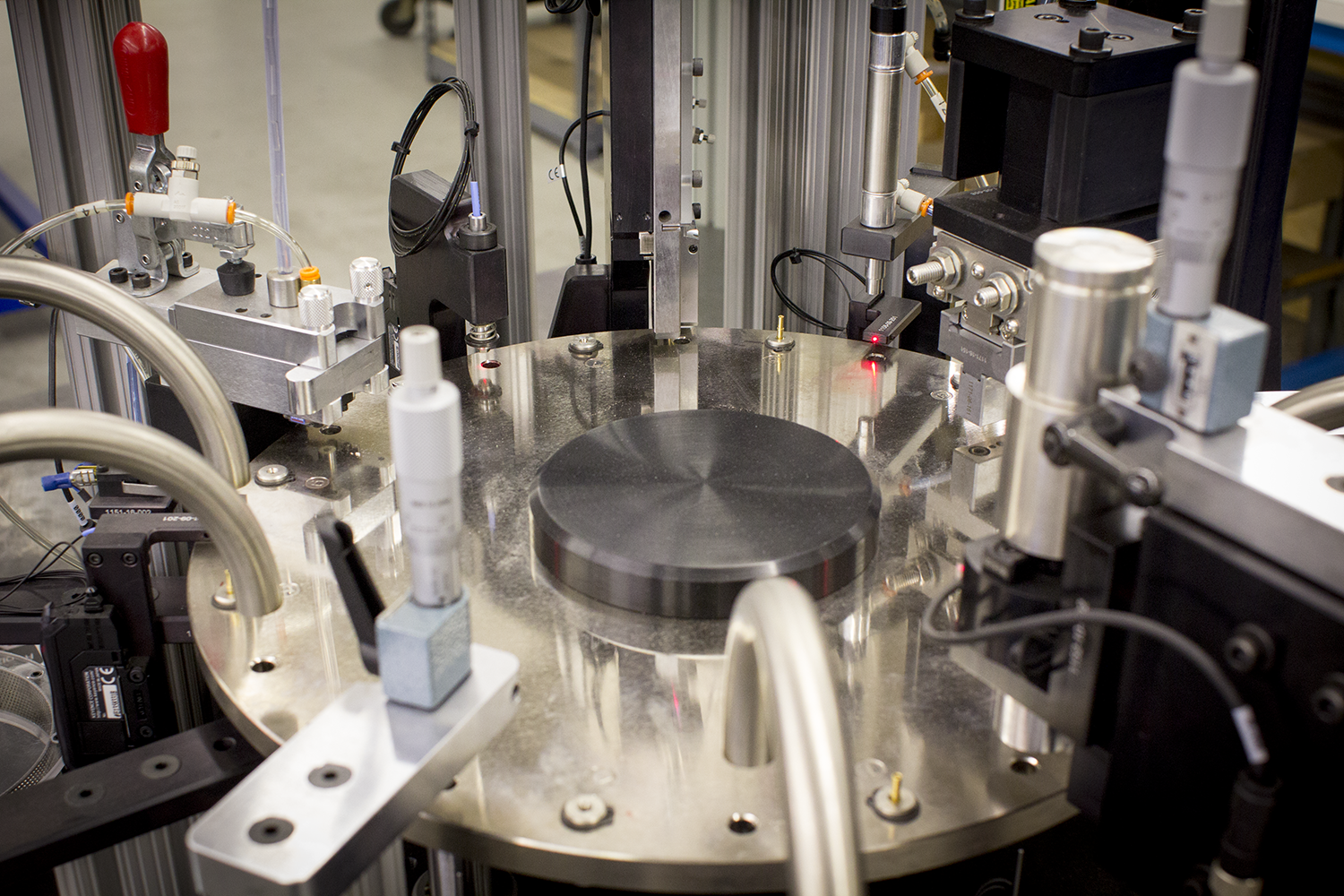

AAI has developed a signature high density profile for multi-station reel fed machines providing a compact and yet easily maintainable approach to minimum footprint automation. Heavy gauge steel machine platforms are powder coated and provide ground steel work surfaces. Hardened chrome plated tooling and anodized alloys provide a corrosion free work environment.

An automated, high volume, machine produces board-to-board connectors at a rate of 40 units per / min. Precision cam operated work stations insert contacts into insulators that are transferred by walking beam. This high density reel fed system orients, aligns and places selective plated contacts into insulators followed by insertion and position verification. A vision inspection station and additional sensors perform "High Pot" and final configuration checks. Accepted components are loaded into trays for packaging.

Contact

Contact

Automated Applications, Inc.

5212 Kazuko Court

Moorpark, CA 93021

USA

T: +1-805-529-2424 (direct)

F: +1-805-529-8630